Conventional Fire Detection and Control Systems

Reliable conventional fire detection & control systems that support a wide range of fire suppression systems for most industrial and commercial applications.

2 and 4-Wire Conventional Smoke Detectors

The 700 Series conventional smoke detector is an interchangeable head and base detector with a light scattering optical sensor that provides an excellent response to a wide range of fires.The 700 Series consists of two and four wire conventional photoelectric smoke, as well as photoelectric smoke with heat detectors.

The 700 Series smoke detectors were the industry’s first conventional self-diagnostic detectors specifically designed for the demands of commercial and industrial environments. If the detector drifts out of its UL Listed sensitivity range or fails internal diagnostics, the alarm LED flashes once a second to indicate a trouble condition. This meets NFPA 72 field sensitivity testing requirements without the need for external meters.

Additional diagnostic information is activated by applying a magnet near the detector’s integral reed switch. This initiates a self-diagnostic routine and provides visual indication of sensitivity level, or if service is required. The magnet test causes the LED to blink. The number of blink counts corresponds to a smoke detector sensitivity range. And, if they become dirty over time, the 700 Series detectors automatically adjust the alarm threshold through builtin drift compensation. If the detector ever does need to be cleaned, the patented field replaceable optical chamber makes cleaning a snap.

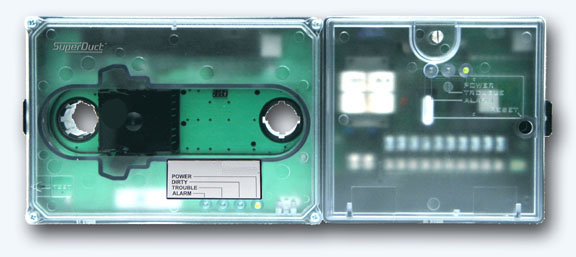

2-Wire Duct Smoke Detector - SuperDuct Series

SuperDuct is a slim feature-rich alternative to bulky duct smoke detectors. Designed for easy installation and superb reliability, SuperDuct represents the perfect balance of practical design and advanced technology.SuperDuct detectors feature a unique design that speeds installation and simplifies maintenance. Removable dust filters, conformally coated circuit boards, and optional water-resistant gaskets keep contaminants away from components, ensuring years of trouble-free service. When cleaning is required, the assemblies come apart easily and snap back together in seconds.

SuperDuct detectors use differential sensing to prevent gradual environmental changes from triggering false alarms. A rapid change in environmental conditions, such as smoke from a fire, causes the detector to automatically signal an alarm condition but dust and debris accumulated over time does not change alarm sensitivity.

The detector assembly cover provides easy access to the smoke sensor, its wiring connections, sample and exhaust tube fittings, and the smoke chamber itself. Air enters the detector’s sensing chamber through a sampling tube (ordered separately) that extends into the duct and is directed back into the ventilation system through an exhaust tube (included). The difference in air pressure between the two tubes pulls the sampled air through the sensing chamber. When a sufficient amount of smoke is detected in the sensing chamber, the detector initiates an alarm.

4-Wire Duct Smoke Detector - ESD-4W

The SuperDuct smoke detector is the most advanced and most reliable device in its class. Designed for easy installation and superb reliability, SuperDuct represents the perfect balance of practical design and advanced technology.Reliability and stability are two features built into every SuperDuct detector. SuperDuct features environmental compensation with patented differential sensing. This achieves a level of stability and reliability never before achieved for devices of this type. With differential sensing, SuperDuct sensors are immune from sensitivity drift – a common cause of false alarms. Every eight minutes the SuperDuct sensor checks its environment for dirt, humidity other conditions that normally interfere with sensor operation, and automatically adjusts its sensitivity to compensate. The result is unparalleled reliability and rock solid stability – two features essential to any duct smoke detection application.

Sensitivity testing and diagnostics reveal some of the most exciting innovations built into SuperDuct. With the ingenious SuperDuct remote test station, a sensitivity test can be performed at any time from the safety and comfort of a maintenance office or utility room. Operated either by key or by magnet, the one-gang station also performs alarm tests for detectors connected to a single controller. Detectors may also be tested at the controller via a test switch, or they can be tested individually in the field with a simple to operate magnetic test tool. Access to the magnetic reed switch does not require the detector cover to be removed, so testing can be performed quickly and easily.

A dedicated dirty/trouble LED on each unit offers immediate at-a-glance information even when the cover is closed.

AEGIS™ 2.0 Conventional Control Unit

The AEGIS 2.0 Conventional Control Unit is a fire suppression-focused single hazard control unit that provides configuration flexibility in a compact footprint and can be ordered with or without door mounted Manual Release and Abort switches.Listed for use with a wide range of suppression systems, the AEGIS™ is compatible with Clean Agents, CO2, Wet and Dry Chemical Systems, Halon, Sprinkler, Deluge, Pre-Action, Foam and Foam-Water systems. Engineered for easy installation, maintenance and use, the AEGIS is ideal for small to mid size special hazard applications. Equipped with a high-degree of programming flexibility and an ample power supply, the AEGIS delivers the continuous fire protection required by a modern industrial, high-tech world.

AEGIS™-XLT Conventional Control Unit

The AEGIS-XLT Control Unit supports a large range of release on and pre-discharge time settings and provides features for LP CO2, Watermist and Spurt applications.The AEGIS-XLT Control Unit is listed for use with a wide range of suppression systems and can be used to control Kidde Fire Systems’ ECS™ and ADS™ Clean Agents, HP CO2, LP CO2, WHDR™ Wet Chemical and IND™ Dry Chemical systems as well as FENWAL® Initiators, Chemetron® release equipment, sprinkler supervisory, deluge/pre-action, foam and foam/water systems.

With its large range of configuration options and settings, NEMA 1, NEMA 4 and NEMA 12 enclosures, the AEGIS-XLT Control Unit is ideal for LP CO2, Watermist and Spurt applications protecting assets in industrial, manufacturing, high-tech and commercial environments.

Electronic Heat Detectors, Models THD-7052 and THD-7053

Both detectors have advanced solid-state, low-voltage, surface-mount circuitry and are designed for 2-wire and 4-wire installation using the appropriate detector base.The THD-7052 and THD-7053 are thermistor-based electronic heat detectors with a 135°F (57°C) fixed temperature set point. In addition, the THD-7052 model has a Rate-Of-Rise of temperature detection feature rated at 15°F (8.3°C) per minute. Two Red Light Emitting Diodes are located diametrically opposite each other to allow 360-degree viewing. Both LEDs continuously indicate the operating condition of the Detector. During standby, the LEDs flash once every six seconds. During alarm, both LEDs light steady at full brilliance. A double flash every six seconds indicates a detector with a thermistor trouble. An optional base is available to provide remote LED function. A unique gated output circuit design provides improved stability and transient suppression. Special signal processing techniques verify the presence of smoke before the detector will alarm.

The detectors are designed for Open Area Protection (UL 521) and may be installed in systems intended for Releasing Device Service through use of a compatible fire alarm control panel.

PRODUCT INQUIRY

Have a question or need more details? Use the button below to contact us.

Get a Quote

We are committed to provide quality products and services Contact Us